flotation ore processing plant technical

Ore Processing Plant/ Ore Beneficiation Plant/ Flotation ...

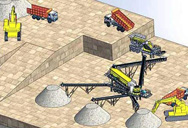

2021-11-30 · Ore processing plant is divided into magnetic separation, flotation separation and gravity concentration. The choice of equipment is in accordance with different mineral features and the common equipment includes vibrating feeder, stone crusher, ball mill, flotation machine, magnetic separator, screener and dryer.

[خذ المزيد]

(PDF) Flotation of iron ore processing plant tailings

2006-1-1 · Evaluation of tailings from processing plants is always an important issue. Lead-Zinc ore tailings containing 3.12% Zn, 3.43% Pb, 0.71 g/t Au and

[خذ المزيد]

Flotation - Mineral Processing & Metallurgy

2016-1-11 · This, of course, will vary with the nature of the ore. In one plant that employs gravitation previous to flotation the fine sand and slime only are treated

[خذ المزيد]

Ore Properties And Selection of Flotation Technology ...

2021-12-23 · The nature of the ore mainly refers to the mineral composition in the ore, the content and proportion of various minerals, the intergrowth characteristics of useful minerals and the symbiosis characteristics between minerals, the isomorphic impurities in the ore, and the existence form of the mineral (if it is primary Mineral or secondary ore, sulfide ore or oxide ore,

[خذ المزيد]

flotation | ore dressing | Britannica

flotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition—that is, the surfaces are either repelled or attracted by water.The flotation process was developed on a commercial scale early in the 20th century to remove very fine mineral particles that formerly had gone to waste in gravity

[خذ المزيد]

RCS™ flotation solution - Outotec

2020-3-3 · process, your plant will experience: RCS™ flotation concept Optimal mineral recovery in a flotation circuit depends on the capacity to adapt to metallurgical variability in the ore being processed. Recognizing the need for a solution that addresses these challenges, has made several advances in flotation design and technology.

[خذ المزيد]

Iron Ore Processing,Crushing,Grinding Plant Machine

Based on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing technologies, such as gravity separation, magnetic separation, flotation, etc., to improve the grade of TFe of the concentrate and get the best yield.

[خذ المزيد]

Pioneer Flotation Launch vFINAL - Petropavlovsk PLC

2021-6-1 · Technical Launch of the Pioneer Flotation Plant Petropavlovsk PLC ("Petropavlovsk" or the "Company" or, together with its subsidiaries, the "Group") today announces the technical launch of the Pioneer flotation plant, the Company’s second facility for processing refractory gold ore and producing flotation concentrate.

[خذ المزيد]

Estimated Water Requirements for the Conventional ...

2012-5-3 · Figure 1 is a generalized diagram of a conventional copper flotation plant from the point where ore first enters the circuit to the production of concentrate and tailings. To prepare ore for the flotation process, run-of-mine ore, which may contain from about 2 to 5 percent water, by weight, when mined, is

[خذ المزيد]

Froth Flotation Process - Mineral Processing & Metallurgy

2021-1-20 · The Froth Flotation Process is about taking advantage of the natural hydrophobicity of liberated (well ground) minerals/metals and making/playing on making them hydrophobic (water-repel) individually to carefully separate them from one another and the slurry they are in. For this purpose we use chemicals/reagents: Frothers (MIBC) is what allows the formation of air bubbles.

[خذ المزيد]

Ore Properties And Selection of Flotation Technology ...

2021-12-23 · The nature of the ore mainly refers to the mineral composition in the ore, the content and proportion of various minerals, the intergrowth characteristics of useful minerals and the symbiosis characteristics between minerals, the isomorphic impurities in the ore, and the existence form of the mineral (if it is primary Mineral or secondary ore, sulfide ore or oxide ore,

[خذ المزيد]

(PDF) Flotation of iron ore processing plant

2006-1-1 · Evaluation of tailings from processing plants is always an important issue. Lead-Zinc ore tailings containing 3.12% Zn, 3.43% Pb, 0.71 g/t Au and 74 g/t Ag was subject to this study.

[خذ المزيد]

RCS™ flotation solution - Outotec

2020-3-3 · process, your plant will experience: RCS™ flotation concept Optimal mineral recovery in a flotation circuit depends on the capacity to adapt to metallurgical variability in the ore being processed. Recognizing the need for a solution that addresses these challenges, has made several advances in flotation design and technology.

[خذ المزيد]

FROTH FLOTATION : RECENT TRENDS Flotation of

2011-12-1 · the process and remarkable development taken place in flotation technology and its ancillary systems, it has now become possible to recover fine grained sulphide minerals from complex ore deposits, whose processing was earlier considered un-economical. Today, about 400 million tons of sulphide ore is treated annually by flotation process worldwide.

[خذ المزيد]

flotation | ore dressing | Britannica

flotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition—that is, the surfaces are either repelled or attracted by water.The flotation process was

[خذ المزيد]

Iron Ore Processing,Crushing,Grinding Plant

Based on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing technologies, such as gravity separation, magnetic separation,

[خذ المزيد]

Froth Flotation Process - Mineral Processing &

2021-1-20 · “The single most important method used for the recovery and upgrading of sulfide ores”, that’s how G. J. Jameson described the froth flotation process in 1992. And it’s true: this process, used in several processing

[خذ المزيد]

Pioneer Flotation Launch vFINAL - Petropavlovsk PLC

2021-6-1 · Technical Launch of the Pioneer Flotation Plant Petropavlovsk PLC ("Petropavlovsk" or the "Company" or, together with its subsidiaries, the "Group") today announces the technical launch of the Pioneer flotation plant, the Company’s second facility for processing refractory gold ore and producing flotation concentrate.

[خذ المزيد]

Estimated Water Requirements for the Conventional ...

2012-5-3 · Figure 1 is a generalized diagram of a conventional copper flotation plant from the point where ore first enters the circuit to the production of concentrate and tailings. To prepare ore for the flotation process, run-of-mine ore, which may contain from about 2 to 5 percent water, by weight, when mined, is

[خذ المزيد]

Improving recovery of iron using column flotation of iron ...

2020-11-1 · Iron ore slimes sample was collected from a slime pond at Kiriburu iron ore processing plant, Jharkhand, India. XRD: hematite, goethite and limonite, quartz, kaolinite, gibbsite and magnetite. The sample contains 58.24% Fe, with 4.72% SiO 2, 3.47% Al 2 O 3, and had 5.18% LOI. The beneficiation of iron ore slimes by selective flocculation was ...

[خذ المزيد]

FROTH FLOTATION : RECENT TRENDS Flotation of

2011-12-1 · the process and remarkable development taken place in flotation technology and its ancillary systems, it has now become possible to recover fine grained sulphide minerals from complex ore deposits, whose processing was earlier considered un-economical. Today, about 400 million tons of sulphide ore is treated annually by flotation process worldwide.

[خذ المزيد]

Flotation Plant, Mineral Separation Plant, Flotation ...

2021-12-23 · Working process of flotation plant The whole flotation plant consists of jaw crusher, ball mill, spiral classifier, stirring tank, flotation machine, concentrator and dryer, etc. Mineral separation plant is high-efficient and energy-conserving. Flotation separation process 1.

[خذ المزيد]

FLOTATION PLANT DESIGN AND PRODUCTION

SGS MINERALS SERVICES TECHNICAL BULLETIN 2005-3 2005 FLOTATION PLANT DESIGN AND PRODUCTION PLANNING THROUGH GEOMETALLURGICAL MODELLING AUTHORS: D. BULLED AND C. MCINNES ABSTRACT The key to successful flotation plant design, production planning and mine/ mill optimisation is a solid understanding of the resource to be

[خذ المزيد]

Pilot Flotation Plant - Mining and Mineral Processing ...

Pilot Flotation Plant. This set of pilot flotation plant is suitable for the laboratory of the ore dressing plant, mineral processing technology research institute, the university, Geology industry and metallurgical industry to do the flotation technology research on the gold ore,non-ferrous metals ore, non-metal ores, in order to provide reliable technical parameters for industrial production ...

[خذ المزيد]

Estimated Water Requirements for the Conventional ...

2012-5-3 · Figure 1 is a generalized diagram of a conventional copper flotation plant from the point where ore first enters the circuit to the production of concentrate and tailings. To prepare ore for the flotation process, run-of-mine ore, which may contain from about 2 to 5 percent water, by weight, when mined, is

[خذ المزيد]

PHOSPHATE PRODUCERS IMPROVE PLANT

2016-5-6 · concentrator was converted from mechanical flotation cells to column flotation cells over a period of 2 years as part of a program to reduce plant operating costs. The ore is a volcanic phosphate ore containing approximately 20 %P 2 O 5 (27% to 28% CaO) primarily as apatite. Principal impurities are barite (9% to 15% BaSO 4), hematite (19% to ...

[خذ المزيد]

Treatment of Mineral Processing Wastewater in Flotation

2021-4-28 · The treatment process is shown in Figure 2. After the wastewater has been coagulated and settled for 24 hours, the final quality indicators of the water discharged are as follows: Pb 2 + 0.1mg/t, Zn 2 + 0.2mg/t, Cu 2 + 0.1mg/t, Cd 2 + 0.09mg/t, F- 4mg/t, S-0.1mg/t, COD25mg/t, pH=3. The water quality complies with the national industrial ...

[خذ المزيد]

Processing Spodumene by Froth Flotation for Lithium

2016-5-9 · Lithium Ore (Spodumene) Flotation. The conditioned pulp is diluted to approximately 20% solids for flotation in “Sub-A” Flotation Machines of standard steel construction. The cell to cell type machine with spitzkasten and froth

[خذ المزيد]

Pioneer Flotation Launch vFINAL - Petropavlovsk PLC

2021-6-1 · Technical Launch of the Pioneer Flotation Plant Petropavlovsk PLC ("Petropavlovsk" or the "Company" or, together with its subsidiaries, the "Group") today announces the technical launch of the Pioneer flotation plant, the Company’s second facility for processing refractory gold ore and producing flotation concentrate.

[خذ المزيد]- differences between single and double toggles jaw crushers

- crusher machine bearing roller

- gold processing plant for alluvial

- parts of gyratory crusher

- crusher conveyor systems for sale

- hp tramp release cylinder

- the mill singapore

- flotation equipment details

- partial replacement of sand with quarry dust in nepal

- dijual alat alat pertambangan

- 30 tph crushing plant

- bucket crusher price

- what is conveyor belt made of?

- crawler type mobile cone crushing plant manufacturer

- ore crusher and grinding equipment

- cone crusher operating principles

- calculation of cement ball mill capacity

- operation of gold stamp mill

- water purifier plant

- crusher for sale cheap

- حمله کننده تولید کننده ماشین آلات

- معدات تجهيز مسحوق كربونات الكالسيوم

- آلة كسارة الحجر المستخدمة

- مطحنة الذهب خام الهاتف المحمول

- بيع وشراء سبائك الذهب

- كسارة الحجر في هاملتون للبيع

- ماشین آلات خرد کردن سنگ ریزه

- تهتز الشاشة مع محطم

- الخبث طحن خط الانتاج

- ماليزيا الشركة المصنعة كسارة الصخور

© Copyright - PETER&Xمحطم